Laboratory Services In Cleveland, OH

Chemical, Corrosion, Metallurgical

Welcome to Tensile Testing, your premier machining testing company and laboratory services provider in Cleveland, OH. With our state-of-the-art facilities and experienced team of experts, we offer a wide range of testing services to meet your specific needs. From chemical analysis to corrosion testing and mechanical testing, we strive to deliver accurate and reliable results to our clients.

Chemical Lab Services

At Tensile Testing, we have a dedicated chemical lab that specializes in two types of chemical analysis – OES (Optical Emission Spectroscopy) and Leco (Combustion). Our highly trained chemists utilize advanced equipment and techniques to analyze the elemental composition of various materials. Whether you require analysis for quality control, material verification, or research purposes, our chemical lab can provide you with precise and detailed results.

- Low alloy

- Stainless steel

- Iron

- Tool steel

- Aluminum

- Nickel

- Copper

- Brass

- Hadfield manganese

- Cobalt

- Carbon

- Sulfur

- Hydrogen

- Nitrogen

- Oxygen

Corrosion Lab Services

Corrosion can have a significant impact on the performance and durability of materials. That’s why we offer comprehensive corrosion testing services at Tensile Testing. Our corrosion lab is equipped to perform salt spray testing, humidity testing, coating evaluations, and fabrication of salt spray panels. By simulating real-life exposure conditions, we can assess the corrosion resistance of materials and coatings, helping you make informed decisions about their use in various applications.

Our coating evaluation capabilities include:

- Tape adhesion

- Coating adhesion

- Cure test

- Thumbnail

- Dime scrape

- Pencil hardness

- Abrasion test

- Chip resistance/gravelometer

- Impact resistance

- Burnishing test

- Cross hatch

- Grind saw

- Appearance

- Gloss

- Luster

- Various resistances

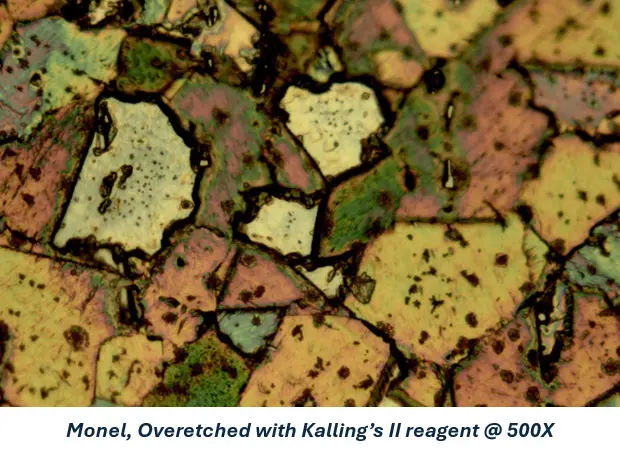

Metallurgical Lab Services

In addition to our chemical, mechanical, and corrosion labs, Tensile Testing also houses a Metallurgical Lab. With modern sample preparation equipment, we ensure that specimens are accurately and efficiently prepared for testing. Our metallurgical lab employs advanced microscopy techniques, such as metallography and microscopy analysis, to examine the microstructure of materials. This allows us to evaluate material properties, identify defects, determine failure modes, and provide valuable insights into the performance and quality of your materials.

Other aspects of Metallurgy includes:

- Microstructure

- Coating Weight

- Conductivity

- Intergranular Attack (IGA)

- Macro Etch / Grain Flow

- Microhardness

- SEM Analysis

Microstructure:

Includes Alpha Case, Banding, Case Depth, Decarb, Ferrite Rating, Grain Boundaries, Graphite in Casting, Nodularity, and Plating.

Coating Weight:

Coating weight or mass can be determined by test methods per ASTM A90 (Zinc), ASTM A428 (aluminum), or ASTM A309 (Terne- alloy coating of lead and tin). These coatings provide protection against corrosion.

Conductivity:

Testing (ASTM E1004) uses reference standards of known value to determine the electrical conductivity of nonmagnetic materials such as aluminum or copper.

Intergranular Attack (IGA)

Intergranular attack (IGA) is a form of corrosion where the boundaries of grains of the material are more susceptible to corrosion than their insides. ASTM A262, Methods A or E is the specification used to detect susceptibility to IGA in austenitic stainless steels.

Microhardness:

Tests (ASTM E384) are done on material that is too thin or too small for Rockwell or Brinell hardness tests. There are two types of indenters Knoop (HK) and Vickers (HV) that are subjected to test forces that range from 1 to 1000 gf. Microghardness is typically used for:

- Decarb Referee

- Case Depth

- Chord Method

- Hardness Surveys

We also perform Vickers hardness (ASTM E92) of metallic materials, using applied forces of 300 gf to 10kgf.

Macro Etch / Grain Flow:

Macroetching (ASTM E340) is the process used on metals and alloys to reveal the macrostructure. The macroetched bars, billets, blooms, and forgings can be rated for their condition using a series of photomacrographs contained in ASTM E340 and ASTM E381. In forgings the technique is used to examine the Grain Flow to ensure it follows the shape of the part. It is also used to describe certain conditions of macro segregation which are often characteristic of consumable electrode remelted materials (ASTM A604). SEM Tensile Testing Metallurgical Laboratory has access to a Scanning Electron Microscope (SEM). It scans the sample surface with a high-energy beam of electrons. Photographs with a magnification up to 25000X are available. SEM is used extensively in failure analysis where fracture surfaces are examined to pinpoint cause of failure.

SEM Analysis

Tensile Testing Metallurgical Laboratory has access to a Scanning Electron Microscope (SEM). It scans the sample surface with a high-energy beam of electrons. Photographs with a magnification up to 25000X are available. SEM is used extensively in failure analysis where fracture surfaces are examined to pinpoint cause of failure.

Why Choose Tensile Testing?

With decades of experience in the industry, Tensile Testing has become a trusted name in laboratory services. Here are a few reasons why clients choose us:

- Expertise: Our team of highly skilled professionals possesses extensive knowledge and expertise in their respective fields. They bring years of experience to every project, ensuring accurate and reliable test results.

- State-of-the-Art Facilities: Our laboratories are equipped with advanced equipment and cutting-edge technology, enabling us to perform a wide range of tests with precision and efficiency.

- Timely Results: We understand the importance of timely results. Our streamlined processes and efficient workflows allow us to deliver accurate test reports within your required timeframe.

- Customized Testing Solutions: At Tensile Testing, we recognize that each client has unique testing requirements. We work closely with our clients to understand their specific needs and provide customized testing solutions tailored to their industry and application.

- Commitment to Quality: Quality is at the core of everything we do. From sample preparation to testing procedures and reporting, we adhere to stringent quality control measures to ensure the highest level of accuracy, reliability, and consistency in our services.

Contact Us Today!

Whether you need chemical analysis, corrosion testing, or mechanical testing, Tensile Testing is here to provide you with comprehensive and reliable laboratory services. Your satisfaction is our top priority, and we are committed to meeting and exceeding your expectations. So contact us today to discuss your testing requirements, and learn how we can assist you in achieving your goals.